Renishaw probe programming enables precise CNC machining by automating measurement tasks․ The Renishaw probe programming manual pdf provides comprehensive guides for setup, calibration, and troubleshooting․ It ensures accurate tool setting, reducing errors and improving efficiency․

Overview of Renishaw Probe Systems

Renishaw probe systems are advanced tools designed for precise measurement and inspection in CNC machining․ These systems, such as the SP25M and MP10, offer touch-trigger and scanning capabilities, enhancing accuracy and efficiency․ The SP25M probe is known for its versatility, supporting both manual and automated operations, while the MP10 is ideal for in-spindle applications․ Renishaw probes integrate seamlessly with CNC machines, enabling real-time data collection and improving production quality․ The systems are supported by comprehensive manuals, like the Renishaw probe programming manual pdf, which detail installation, operation, and calibration․ These resources ensure users can maximize the potential of their probes, whether for tool setting or complex part inspection․ By streamlining measurement processes, Renishaw probes contribute significantly to modern manufacturing workflows․

Importance of Probe Programming in CNC Machining

Importance of Probe Programming in CNC Machining

Probe programming is essential in CNC machining for achieving precision and efficiency․ It enables automated measurement, reducing human error and optimizing production processes․ By integrating probes like the Renishaw SP25M and MP10, manufacturers can streamline tasks such as tool setting, part inspection, and dimensional verification․ The Renishaw probe programming manual pdf emphasizes the role of accurate programming in ensuring probes function correctly․ Properly programmed probes minimize downtime, reduce material waste, and improve product quality․ They also allow for real-time adjustments, adapting to dynamic machining conditions․ This capability is crucial for maintaining competitiveness in high-precision manufacturing environments, where accuracy and consistency are paramount․ Effective probe programming thus directly contributes to the overall success and profitability of CNC machining operations․

Installation and Setup of Renishaw Probes

The Renishaw probe programming manual guides users through hardware installation, connectivity, and software setup․ Proper alignment and configuration ensure accurate measurements and seamless integration with CNC machines․

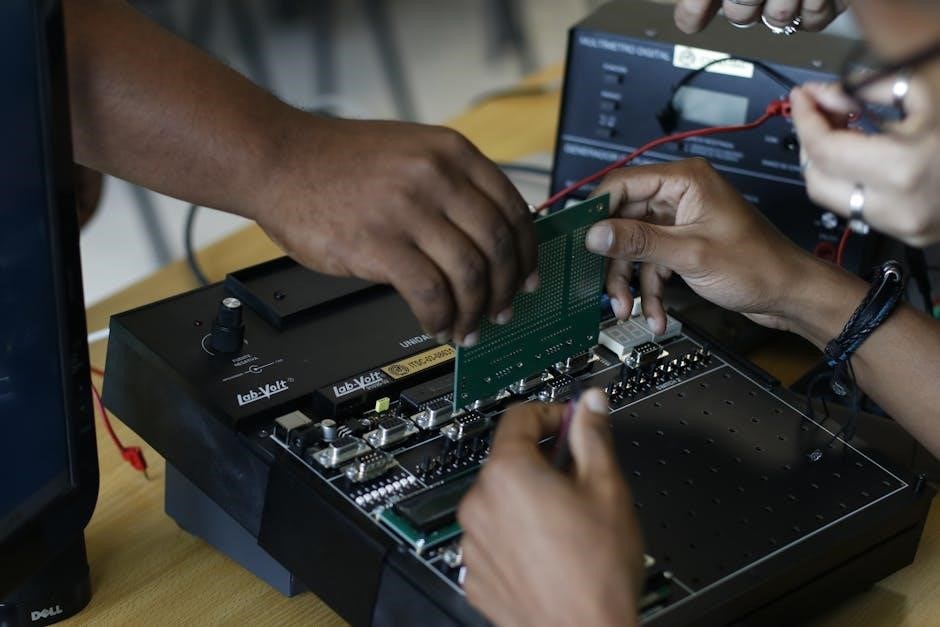

Hardware Installation and Connectivity

Installing Renishaw probes requires careful attention to hardware setup and connectivity․ The probe must be securely mounted on the CNC machine, ensuring proper alignment and stability․ Connecting the probe to the machine’s control system involves using compatible cables and adapters, as specified in the manual․ Power supply and signal transmission must be verified to ensure reliable communication․ Proper grounding and shielding of cables are crucial to prevent interference․ The manual also highlights common installation errors, such as incorrect wiring or loose connections, which can lead to inaccurate measurements․ Following the step-by-step guide ensures optimal performance and precise data collection, minimizing downtime and enhancing machining accuracy․

Software Setup and Configuration

Configuring the software for Renishaw probes involves installing and setting up the Inspection Plus or VQCPS programs․ These tools interface with the probe system, enabling precise control and data acquisition․ The manual guides users through parameter settings, such as probe types, measurement ranges, and communication protocols․ Calibration routines, like setting the probe’s switch-on delay, are also detailed to ensure accurate operation․ Operators must define safe start planes and configure output formats for probe signals․ The software integrates seamlessly with CNC controls, allowing for real-time data processing and macro programming․ Proper configuration ensures reliable performance, while incorrect settings can lead to measurement inaccuracies․ The manual emphasizes the importance of following predefined procedures to achieve optimal results and maintain system integrity․ Regular software updates are recommended to access new features and improvements․ By adhering to these guidelines, users can maximize the efficiency and precision of their Renishaw probe systems․ The manual provides troubleshooting tips for common software issues, such as communication errors or invalid parameter settings, ensuring minimal downtime and uninterrupted production․

Probe Calibration and Initialization

Probe calibration and initialization are critical steps to ensure accurate measurements․ The Renishaw probe programming manual pdf outlines procedures for initializing the probe system, including setting the switch-on delay to prevent stylus deflection․ Users must follow predefined calibration routines to synchronize the probe with the CNC machine․ Proper initialization ensures the probe’s signals are correctly interpreted, avoiding measurement errors․ The manual emphasizes the importance of maintaining the probe’s default settings unless specific adjustments are required․ Incorrect calibration can lead to system malfunctions or inaccurate data․ Regular recalibration is recommended after software updates or hardware changes․ By adhering to the manual’s guidelines, operators can ensure reliable probe performance and precise measurement outcomes․ The process is designed to be user-friendly, with step-by-step instructions to minimize errors and downtime․ Proper initialization also extends the probe’s lifespan by preventing unnecessary wear․ Always refer to the manual for specific calibration procedures tailored to your Renishaw probe model․

Probe Calibration and Configuration

The Renishaw probe programming manual pdf explains the critical processes of probe calibration and configuration․ It details how to set the switch-on delay and synchronize the probe with CNC machines for accurate measurements and reliable performance․

Understanding Probe Calibration Procedures

Probe calibration is essential for ensuring accurate measurements in CNC machining․ The Renishaw probe programming manual pdf outlines detailed steps for calibrating probes, emphasizing the importance of proper switch-on delay settings to prevent stylus deflection during initialization․ It also covers synchronization of the probe with the CNC machine’s coordinate system․ Calibration involves defining the probe’s parameters, such as stylus length and ball diameter, to ensure precise measurements․ The manual provides troubleshooting guides for common calibration errors, such as incorrect offsets or misalignment․ By following these procedures, users can achieve reliable and consistent results in their machining operations․ Proper calibration ensures optimal performance and extends the lifespan of the probe system․

Configuring Probe Settings for Optimal Performance

Configuring probe settings is critical for achieving precise measurements and efficient operation․ The Renishaw probe programming manual pdf details how to optimize settings, such as switch-on delay, to prevent stylus deflection during initialization; It also explains how to configure touch-trigger and scanning parameters to balance speed and accuracy․ Users can define probe-specific settings, including stylus length and ball diameter, to ensure measurements align with the CNC machine’s coordinate system․ The manual provides guidance on synchronizing probe outputs with machine controls and adjusting sensitivity for varying workpiece materials․ Proper configuration enhances reliability, reduces errors, and maximizes the probe’s performance in diverse machining applications․ These settings are essential for achieving consistent and accurate results in CNC operations․

Troubleshooting Common Probe Issues

The Renishaw probe programming manual pdf addresses common issues like calibration errors, connectivity problems, and error codes․ It provides diagnostic steps and solutions to ensure reliable probe operation․

Identifying and Resolving Probe Calibration Errors

Probe calibration errors can disrupt machining accuracy, requiring immediate attention․ The Renishaw probe programming manual pdf outlines diagnostic steps to identify issues like stylus deflection or switch-on delays․ It provides detailed procedures for recalibrating probes, ensuring precise measurements․ Common errors include incorrect initialization or misalignment, which can be resolved by following the manual’s troubleshooting guide․ Additionally, the document covers error codes, offering solutions to restore optimal probe functionality․ By adhering to these guidelines, users can minimize downtime and maintain consistent machining quality․ The manual emphasizes the importance of proper calibration techniques to prevent recurring issues and ensure reliable probe performance in CNC operations․

Addressing Common Probe-Related Error Codes

The Renishaw probe programming manual pdf provides a detailed guide for interpreting and resolving common error codes․ These codes often indicate issues such as probe misalignment, stylus damage, or communication faults․ The manual outlines step-by-step solutions, including recalibration procedures and system resets․ Users can quickly diagnose problems by referencing the error code list, ensuring minimal downtime․ For instance, codes related to switch-on delays or deflection errors are addressed with specific troubleshooting steps․ The document also recommends preventive measures to avoid recurring issues․ By following these guidelines, operators can efficiently resolve errors and maintain seamless probe performance, ensuring precise CNC machining operations․ The manual’s clear instructions make it an essential resource for both novice and experienced users․

Advanced Probe Programming Techniques

Advanced probe programming techniques unlock the full potential of your Renishaw probe systems․ Custom macro programming and integration with CNC machines enable streamlined measurement routines, enhancing productivity and precision․

Custom Macro Programming for Renishaw Probes

Custom macro programming for Renishaw probes allows users to create tailored measurement routines, enhancing flexibility and efficiency in CNC machining operations․ By leveraging Renishaw’s advanced software tools, such as VQCPS, users can develop bespoke macros to automate complex probing tasks․ These macros streamline repetitive operations, reduce human error, and optimize machine performance․ The Renishaw probe programming manual pdf provides detailed guidance on macro creation, including syntax, variables, and integration with CNC controls․ Users can design macros for specific applications, such as tool setting, part inspection, or adaptive machining․ This capability is particularly valuable for custom manufacturing workflows, enabling precise control over probing sequences․ With proper training and resources, machinists can unlock the full potential of Renishaw probes through custom macro programming․

Integrating Probes with CNC Machines

Integrating Renishaw probes with CNC machines is essential for seamless measurement and machining operations․ The Renishaw probe programming manual pdf offers step-by-step instructions for connecting probes to CNC controls, ensuring proper communication and synchronization․ This integration allows real-time data exchange, enabling precise tool setting, part inspection, and adaptive machining․ The manual covers hardware installation, software configuration, and troubleshooting common connectivity issues․ By following these guidelines, manufacturers can enhance production accuracy, reduce downtime, and improve overall efficiency․ Proper integration ensures that Renishaw probes function optimally, delivering reliable results in high-precision manufacturing environments․ The manual also provides best practices for maintaining probe performance and compatibility with various CNC systems․

Probe Programming Manuals and Resources

The Renishaw probe programming manual pdf is a vital resource, offering detailed guidance on probe setup, calibration, and troubleshooting․ It ensures optimal performance and accuracy in CNC machining․

Overview of the Renishaw Probe Programming Manual

The Renishaw probe programming manual pdf is a comprehensive guide designed to assist users in mastering probe programming․ It covers essential topics such as installation, calibration, and troubleshooting, ensuring optimal performance of Renishaw probing systems․ The manual provides step-by-step instructions for configuring probe settings, writing custom macros, and integrating probes with CNC machines․ Additionally, it addresses common issues and error codes, offering practical solutions to enhance machining accuracy and efficiency․ Detailed diagrams and examples are included to facilitate understanding․ This resource is indispensable for both novice and experienced users, helping them unlock the full potential of Renishaw probes in various CNC applications․

Additional Resources for Probe Programming

Beyond the Renishaw probe programming manual pdf, users can access supplementary materials to deepen their understanding․ These include online tutorials, webinars, and forums where professionals share insights and solutions․ Renishaw’s official website offers downloadable guides, such as the SP25M installation manual, which complements the main manual․ Additionally, third-party platforms like Manualios․com provide free access to over 240 Renishaw manuals, covering various probe systems․ These resources are invaluable for troubleshooting and exploring advanced techniques, ensuring users can maximize the functionality of their Renishaw probes in CNC machining․ By leveraging these tools, users can enhance their programming skills and maintain optimal probe performance․